SIL Determination

Safety Instrumented Functions (SIF’s) are important elements within many industries for the protection and mitigation of risks. Therefore, it is important to identify the protection requirements of each SIF in respect to its function. The requirement is often described in terms of Safety Integrity Level (SIL). A SIL can be one of four levels, each within a target band known as the Probability of Failure on Demand (PFD), where SIL1 is considered the lowest and SIL4 is considered the highest.

Concept of Risk Tolerability

The purpose of determining the tolerable risk for a specific hazardous event is to state what is deemed reasonable with respect to both the frequency of the hazardous event and its specific consequences.

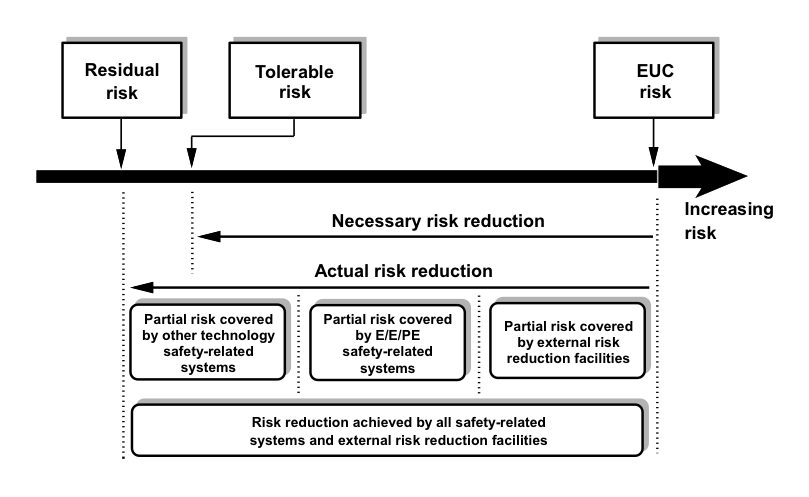

The tolerable risk will depend on many factors. For example, the severity of the consequences or injury, the number of people exposed to danger, the frequency and the duration of the exposure. Important factors will be the perception and views of those exposed to the hazardous event. Risk reduction is achieved by a combination of all the safety protective features, including any associated SIF. The necessary risk reduction to achieve the specified tolerable risk, from a starting point of the risk presented by the Equipment Under Control (EUC), is shown below.

Safety integrity applies to the Electrical / Electronic / Programmable Electronic (E/E/PE) SIF, other technology safety instrumented systems and external risk reduction facilities and is a measure of the likelihood of those systems satisfactorily achieving the necessary risk reduction. Once the tolerable risk has been set, and the necessary risk reduction estimated, the safety integrity requirements for the SIFs can be allocated in terms of the PFD.

| SIL | LOW DEMAND (PFD) |

| SIL4 | ³ 10-5 to < 10-4 |

| SIL3 | ³ 10-4 to < 10-3 |

| SIL2 | ³ 10-3 to < 10-2 |

| SIL1 | ³ 10-2 to < 10-1 |

Methods of SIL Determination

There are various methods in achieving SIL targets qualitatively by Risk Graphs, semi-quantitatively by Layer of Protection Analysis (LOPA) or fully quantitatively by Fault Tree Analysis (FTA).

FAQ’s

What inputs are required by FSES in order to conduct the SIL Determination Study?

As a minimum the following information would be required in order to conduct the workshop:

– Existing PHA / HAZOP report

– P&ID’s

– Cause and Effects Diagrams

– Facilities Design

– Operating Data and Procedures

– Maintenance Data and Procedures

– Interlock List

– Equipment Data Sheets

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

Who is required to attend the SIL Determination Workshop?

As a minimum the following personnel would be required in order to conduct the workshop:

– Process Engineer

– Controls and Instrumentation Engineer

– Process Safety Engineer

– Maintenance representative

– Operations representative

Based on the project requirements, additional personnel may be required to attend the workshop, which will be highlighted within the ToR.

What is the expected output of the SIL Determination Study?

On award of the study FSES will issue a project ToR, which will highlight the assumptions that shall be made in the study, along with the workshop details, methodology and data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, FSES will facilitate the SIL Determination study through a workshop providing the facilitator and scribe. Once the workshop has been conducted, FSES will prepare a SIL Determination report describing the facility, the scope of work, a detailed methodology, the identified SIF’s, initiating events, protection layers, conditional modifiers, the results of the analysis (i.e. SIL requirements for each SIF) and any recommendations based on the discussions during the workshop.

Based on the results of the analysis, FSES can also conduct a Cost Benefit Analysis (CBA) in order to identify if the further risk reduction can be attained.

FSES highly recommend that following on from the SIL Determination study, a SIL Verification analysis is conducted in order to ensure that the SIF’s meet their required SIL targets as per the requirements of IEC 61508 and IEC 61511. Based on the results of the SIL Determination and Verification studies, FSES are also able to assist in writing detailed Safety Requirement Specifications (SRS) for each of the SIFs.

Why FSES?

FSES are a globally renowned facilitators of SIL Determination studies having facilitated 100’s of hours of SIL Determination studies, with a team of TUV Rheinland certified Functional Safety Engineers available for facilitation. FSES can provide SIL Determination studies using semi-quantitative and quantitative techniques such as; Risk Graph (including extended Risk Graph), Risk Matrix, Layer Of Protection Analysis (LOPA) and Fault Tree Analysis (FTA). For more information, or to discuss your needs for conducting a SIL Determination study, please contact us using the form below or email info@fses.global.