Quantitative Risk Assessment

Quantitative Risk Assessment (QRA) is a method which allows for quantitative estimation of risk, given the parameters defining them. The risk is calculated for the potential for safety, environmental or financial impact. the method can be defined as a formal and systematic approach in identifying hazardous events, estimating the likelihood of the hazardous event and the associated consequences.

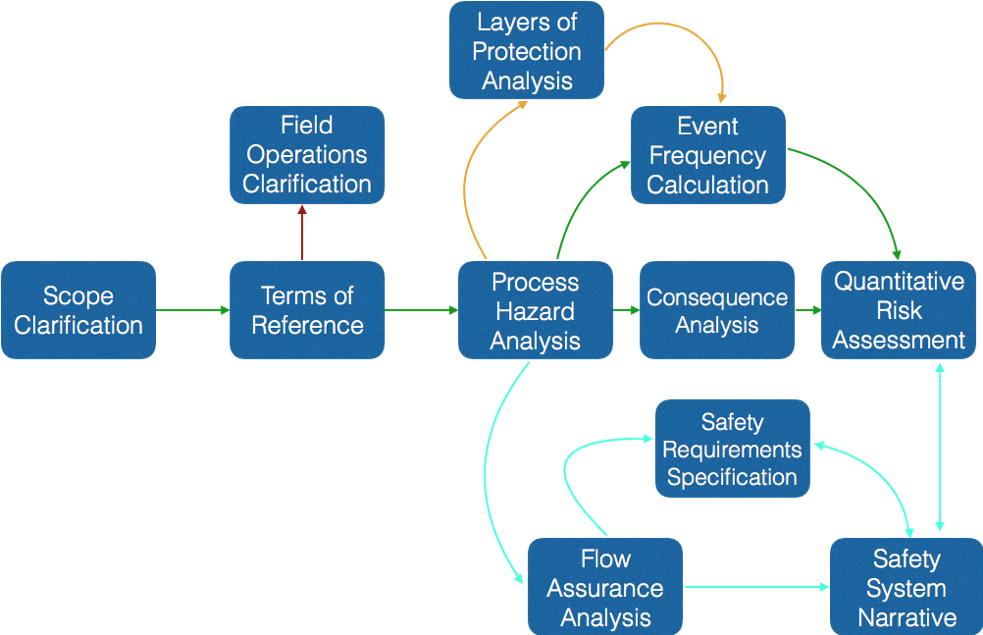

Typical QRA Life Cycle

– Process Hazard Assessment;

– Quantitative estimation of Hazardous Event Frequencies;

– Hazard Severity Assessment and Consequence Analysis;

– Location Specific Risk;

– Individual Risk Per Annum (IRPA) Calculation;

– Potential Loss of Life (PLL) Calculations;

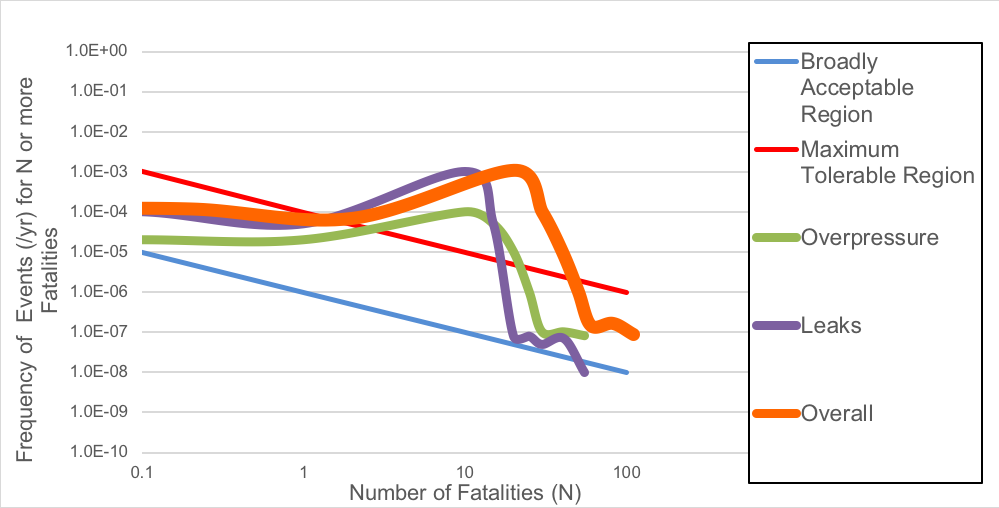

– Frequency and Fatality plot (FN Plots), Cumulative FN Plots;

– Risk Reduction Measure Verification;

– Demonstration of Tolerable Levels of Risk and principle of As Low As Reasonably Practicable (ALARP);

– Sensitivity Analysis;

– System Narrative / Safety Requirement Specification.

Examples

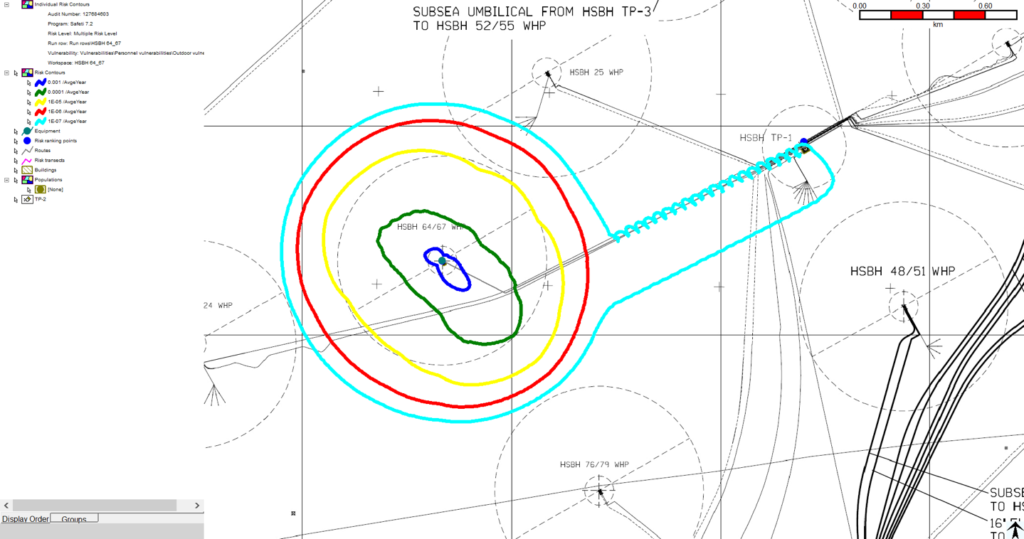

The following are typical graphical representations of the risk contours.

Location Specific Individual Risk (LSIR) Contours represented on Map

FN Plots demonstrating Risk to Personnel On-site

FAQ’s

What software does FSES utilise in order to conduct QRA’s?

FSES are able to utilise their own in-house tool for the calculation of risk. Our consultants are also trained to use commercially available risk analysis tools (i.e. DNV PHAST Risk / SAFETI) when needed.

What inputs are required by FSES in order to conduct the QRA?

As a minimum the following information would be required in order to conduct the workshop:

– P&ID’s

– Cause and Effects Diagrams

– Facilities Design

– Operating Data and Procedures

– Heat and Material balances

– Equipment Rating and Data Sheets

Based on the project requirements, additional information may be required, which will be highlighted within the Terms of Reference (ToR).

What is the expected output of the QRA?

On award of the study FSES will issue a project ToR, which will highlight the assumptions that shall be made in the study, along with the study methodology and data sources that will be utilised as well as any further information required from the client.

Upon acceptance of the ToR, FSES will conduct the QRA and will prepare a report describing the facility, the scope of work, a detailed methodology, the results of the analysis (i.e. IRPA and PLL compared against the risk criteria) and any recommendations for further risk reduction.

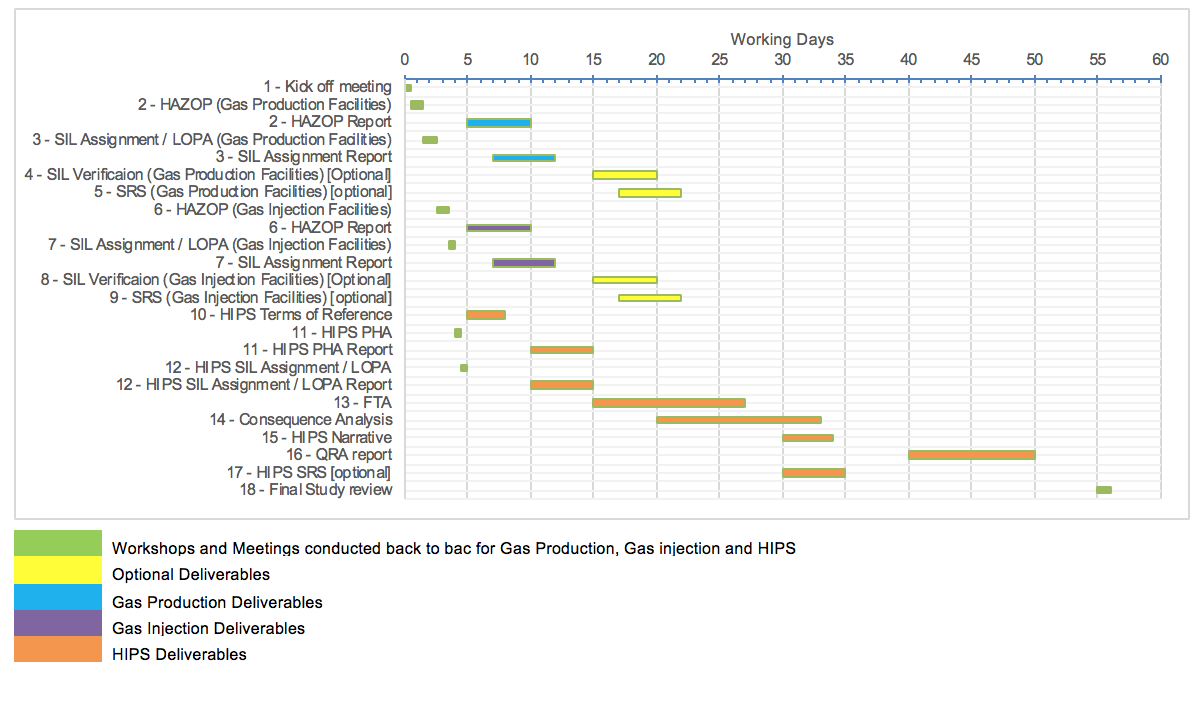

What is the expected Delivery Schedule?

On award of the study, FSES shall develop a project schedule similar to below in order to provide an overview of project deliverables and schedule.

Why FSES?

FSES are a globally renowned providers of QRA studies having conducted a number of high profile onshore and offshore QRA’s in the Middle East and elsewhere including the Safaniya, Marjan, Zuluf and Hasbah facilities amongst others.

For more information, or to discuss your needs for conducting a QRA, please contact us using the form below or email info@fses.global.

Further Information

FSES Quantitative Risk Assessment Life Cycle Methodology – Download here.

FSES Quantitative Risk Assessment Publication in HAZARDEX – Download here.